The primary reason for using a compressed air filter is to remove contamination and improve air quality. Parker's design philosophy of air quality, energy efficiency has led to products that provide highest air quality, lowest power consumption, lowest operational differential pressure, lowest CO2 emissions and lowest total cost of ownership. Since the introduction of the first Parker OIL-X range, Parker has continued to develop both the compressed air filter and the standards governing compressed air quality.

Compressed Air Dryers, Membrane -40°F/C Dewpoint

Balston Membrane Air Dryers combine superior coalescing technology with a proven innovative membrane system to supply clean dry compressed air with dewpoints as low as -40F (-40C), and provide low cost operation with minimal maintenance.

Compressed Air Dryers, Membrane 35°F/2°C Dewpoint

Balston Membrane Air Dryers combine superior coalescing technology with a proven innovativemembrane system to supply cleank dry compressd air with dewpoints as low as -40F (-40C), and provide low cost operatin with minimal maintenanxe.

Compressed Air Dryers for Electrical Cabinets and Enclosures

The meat and dairy industry demands the ultimate in cleanliness and sanitation in its preparation areas. Balston Cabinet Dryers are designed to purge the inside of the cabinets with very dry air that eliminates moisture and premature component failures.

Compressed Air Dryers, PSA Desiccant

The Balston regenerative dryer has safe, 12 VDC electrical controls. To install, simply attach the inlet (60 psig/4.1 BARG minimum) and outlet air lines, plug the electrical transformer into a wall outle-no electrician needed- and the unit is ready for trouble free operation.

Steam Filter for Hospital Sterilization Systems

The 23R Steam Filter for Hospital Steam Sterilization Systems contains a patented Microfibre® filter cartridge in a rugged stainless steel housing designed for steam service. Standard intems include a stainless steel condensate drain and high quality bleeder valve. The system arrives ready for easy installatin.

Vacuum Pump Exhaust Filters

Parker Balston Vacuum Pump Exhaust Filters remove 99.9% or 0.1 micron oil mist and smoke particles from vacuum pump exhaust even when its is saturated with oil. These filters are available for both hazardous and non-hazardous applications, and offer superior chemical and solvent resistance.

The high efficiency filters cartridge continuously drains the collected liquid, allowing the user to recover expensive lubricating oil.

Compressed Air Filters - HX Series

Parker’s special UNI-CAST formed elements and our deep bed pleated elements provide lower pressure drop and less frequent changeouts, saving time and money.

HX-Series filters can be used in applications ranging from general shop air all the way up to those which call for extremely critical performance requirements, such as instrument air, breathing air, food and beverage or automotive assembly plant paint systems.

Ultra Dry Gas Generator

Parker Model UDA-300 Compressed Air Dryer provides ultra-dry, purified compressed air to analytical instruments. Designed for NMR instruments, the Parker compressed air dryer will reduce the dewpoint of compressed air to -100°F (-73°C).

Atomic Absorption Gas Purifier

Parker Atomic Absorption (AA) Gas Purifier is an engineered, wall mountable system designed to purify gases commonly used with AA Spectrophotometers. Consisting of two independent filtration systems for purifying compressed air and for acetylene gas.

TOC Gas Generators

Parker’s TOC Gas Generators produce carrier/combustion gas, from an existing compressed air supply for TOC instruments. Eliminates the need to purchase expensive, inconvenient, high pressure cylinders of air, nitrogen, or oxygen.

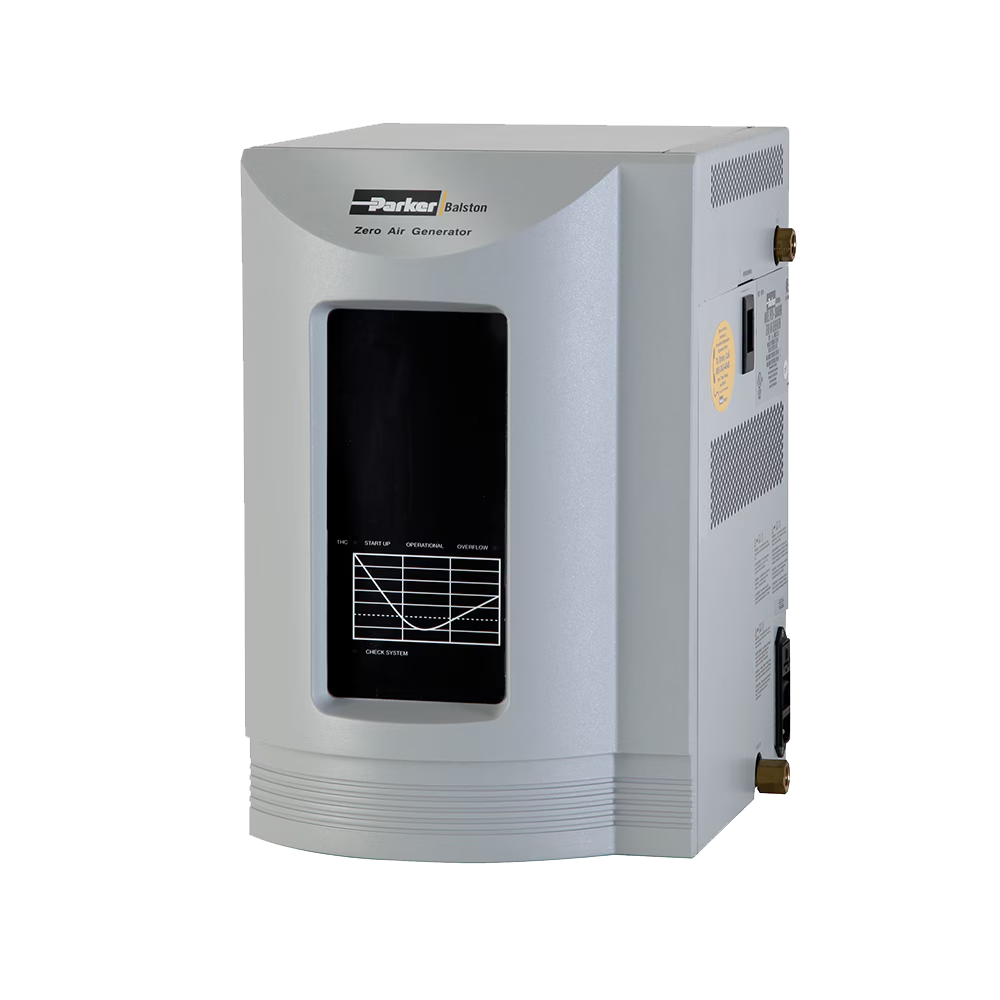

Zero Air Generators

Parker Zero Air Generators are systems manufactured with state-of-the-art, highly reliable components engineered for easy installation, operation, and long term performance. Pare Zero Air Generators are much easier to install than dangerous high pressure gas cylinders, and only need to be installed once! All that is required is a standard compressed air line and electrical outlet.

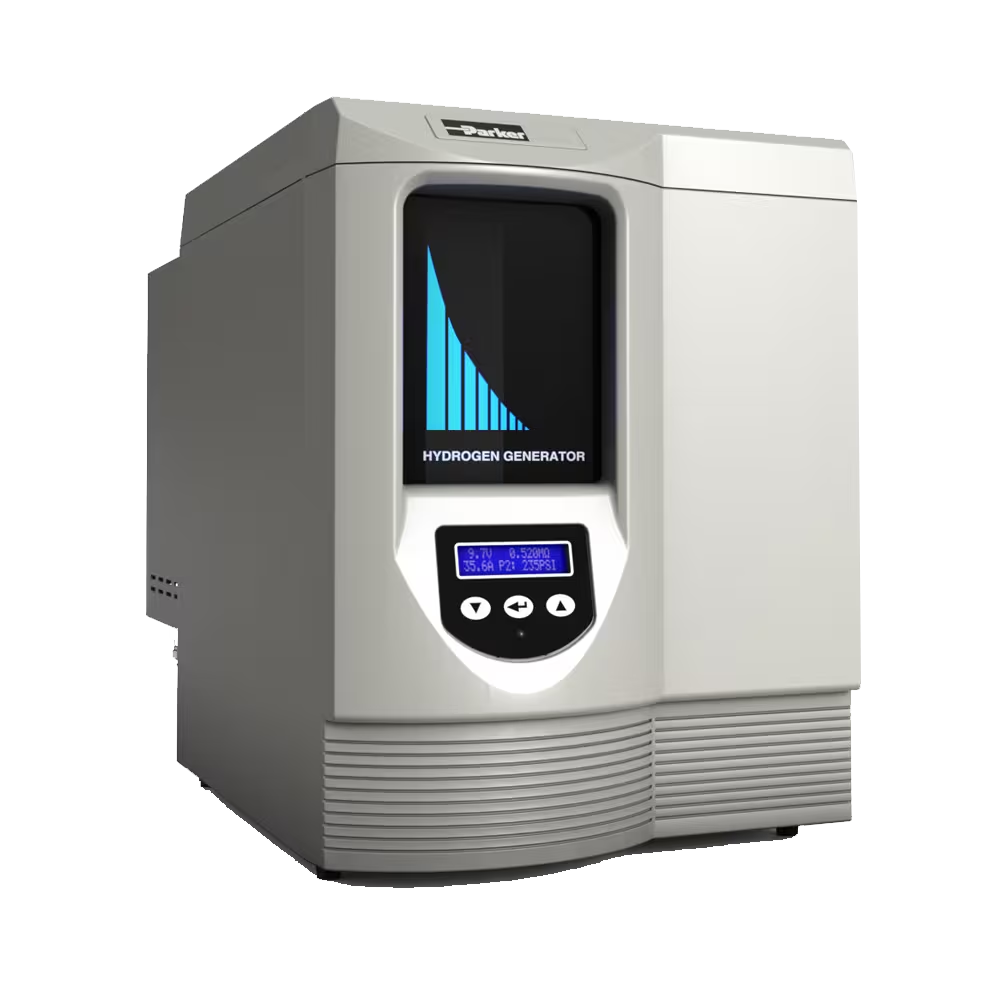

Hydrogen Generators for Fuel Gas

Parker fuel gas hydrogen generators utilize proton exchange membrane, which eliminates the use of liquid electrolytes with hydrogen generators. Proven in over 40,000 GC installations worldwide. Parker generators are the most reliable hydrogen generators on the market.

FID Gas Stations

Parker Balston's FID-1000NA, FID-2500NA, and FID-3500NA Gas Stations provide both hydrogen gas and zero grade air to FID detectors on gas chromatographs. These systems are specifically designed to provide fuel gas and support air to 10-11 flame ionization detectors, flame photometric detectors or total hydrocarbon analyzers.

Nitrogen Generators for Solvent Evaporation

Parker NitroVap Generators can provide clean, ultra-dry nitrogen to samle evaporators. The Nitrovap generators are complete systems with state-of-the-art, highly reliable components engineered for easy installation, operation and long term performa nce. These systems offer high nitrogen output flows in a minature cabinet.

Nitrogen Generators for LCMS Applications

Parker Balston offers a wide range of nitrogen gas generators for liquid chromatograph with mass spectrometric detector (LCMS)applications. Models are offered to supply LCMS grade nitrogen as the curtain gas. The nitroflow60D will supply both nitrogen and dry air (-40F/40C dewpoints) as the exhaust gas. Models with built in compressors are available for labs without a compressed air supply.

Finite J-Series High Pressure Compressed Air & Gas Filters

Parker’s Finite J-Series filters are designed to filter contaminants such as rust, pipe scale, compressor lube oil, and water from compressed gases. These filters are often used in high pressure Compressed Natural Gas (CNG) systems.

Compressed Air & Gas - Up to 300 PSIG - FDD Desiccant Dryer Series

Parker's finite FDD Desiccant Dryer Series unique inline ai/gas dryer system is engineered for easy desiccant changeouts, longer life, and lower pressure drop. The FDD Series is designed to remove water vapor and aerosols at poiont-of-use for intermittent flows up to 60 SCFM. Finite dryers do not require steady flow for constant dew point suppression.

FFC-112 Compressed Air & Gas Replacement Elements - Up to 3600 PSIG

Parker Finite inline compressed natural gas FFC-112 filter series features a light weight robust construction, and is designed to protect critical engine components from contaminants in CNG fuel. Compressed natural gas powered vehicles such as airport shuttles, delivery vehicles, medium and light duty trucks and buses, taxis and passenger vehicles have come to rely on the Parker Finite FFC-112 Filter Series to protect critical engine components from contamination present in CNG fuel.

FFC-113 Compressed Air & Gas Replacement Elements - Up To 3600 PSIG | Product Series

Parker Finite Compressed Natural Gas Replacement Elements feature a light weight robust construction and are designed to protect critical engine components from contaminants in Compressed Natural Gas (CNG) fuel.

Exhaust Coalescing Silencer - up to 100 PSIG

Parkers finite filter operation's ECS are constructed from the same materials that are used in our oil removal coalescing filter elements. Parker Finite's UNI-CAST seamless design ensures media uniformity and strength. This proven technology provides high coalescing efficieny with low pressure drop.

Replacement Elements for Finite H-Series Compressed Air and Gas Filters

Replacement Elements for Finite H-Series Filter Housings

Mist Eliminator - PME Series | Product Series

Parker Airtek's Mist Eliminator is designed to optimize oil removal and ensure extremely low pressure drop, protect against catastrophic air/oil separator failure, and is strong enough to withstand the most arduous operating conditions.

Contact a Dedicated TFS Representative

TFS has developed an extensive product offering through partnerships with industry leading manufacturers. Count on us to meet your needs while improving your facility’s operation and efficiency.