Finite ASME Replacement Elements | Product Series

Parker’s Finite large capacity ASME filter replacement elements have been designed to incorporate large flow capacities for maximum performance with low differential pressures.

Parker Finite offers the filter media grades ensuring that we have the correct media choice for nealy any appliation requirement. Parker offers 8 media choices ranging from the Finite's standard UNI-CAST coalescer in grades 6,8,and 10, a high temperature coalescer in grade 6,8, and 10, two pleated coalescer s, a bulk liquid removal, particulate reomoval, and an oil vapor (odor) removal elements.

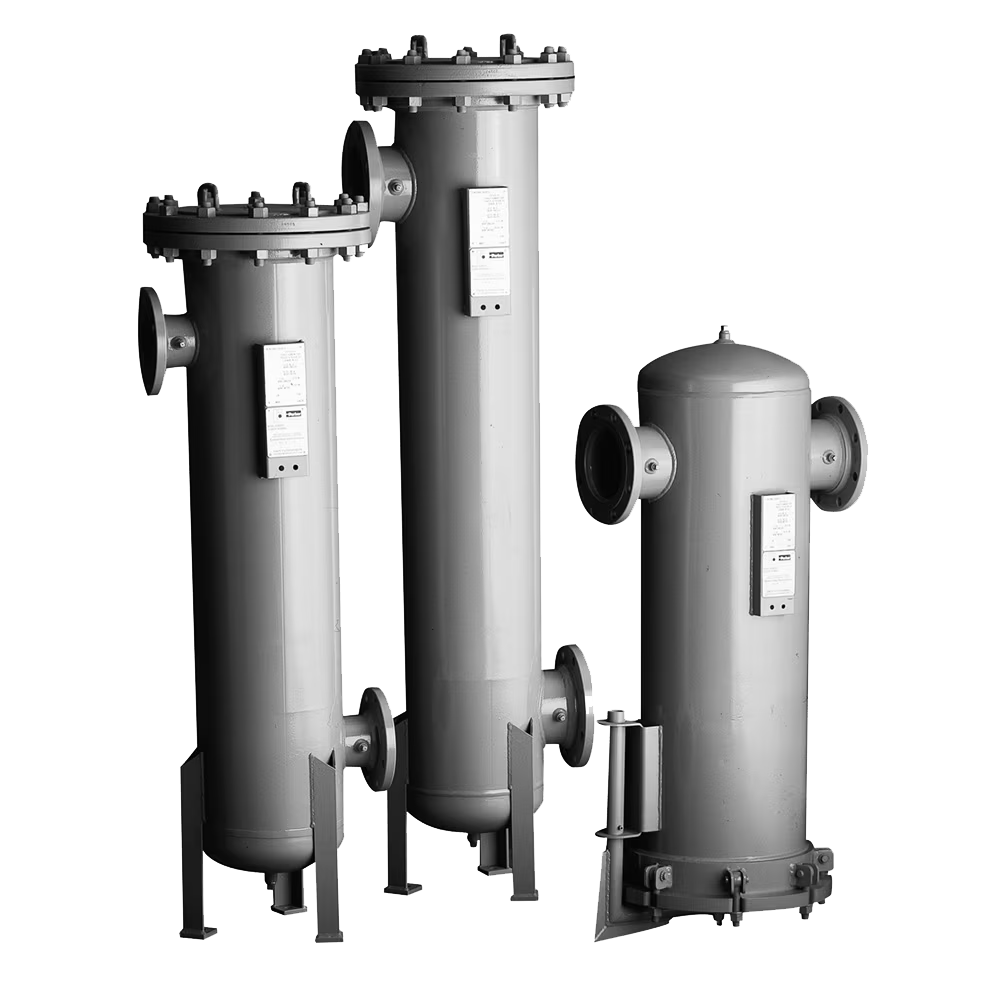

Compressed Air & Gas - Up to 185 PSIG - ASME Vessels | Product Series

Parker's Finite filters large capacity ASME filter vessels have been designed specifically for our coalescing elements and incorporate large sump capacities and generous exit cavities or maximum performance with low differential pressures.

All units are "U" stamped and conform to ASME section VIII standard code for pressure vessels. With flow capacities to 37,000 SCFM and optional materials of construction, most compressor source filtration requirements can be met.

Finite H-Series Filter Housings | Product Series

Submicronic contaminants in compressed air systems plug orifices of sensitive pneumatic instrumentation, wear out sealsk, erode system components, reduce the absorptive capacity of desiccant air/gas dehydrators, foul heat transfer surfaces, reduce air tool eficiency, and damage finished produts. The results include product rejects, lost production time and increase manintenance expense.

Balston Replacement Filter Elements

Balston replacement filter cartridges offer high efficiency filtration with superior quality and consistent performance. These robust, durable cartridges are designed to be used in Balston branded filter housings.

Balston 2000 Series Compressed Air Filters

Parker Balston 2000 series compressed air and gas filters remove contaminants at an efficiency of up to 99.99% for 0.01 micron particles and droplets.

6000 Series Compressed Air Filters

Parker Balston 6000 series stainless steel compressed air filters protect equipment and delicate instruments from the dirt, water, and oil usually found in compressed air and other gases. These filters will remove contaminants at a veery high efficiency-up to 99.99% for 0.01 micron particles and droplets.

Natural Gas Filters 6 IN to 10 IN Line Size

Parker Balston High Flow Rate Natural Gas Filters offer high efficiency coalescing filtration and are specifically designed to remove suspended liquids and dirt from pipeline natural gas.

Each filter cartridge is mounted on a permanent filter holder with a vibration-resisteant removable tube retainer. The cartridges are self-gasketing and tthe holder is deisgned for a perfect seal, even when the cartridge is replaced by an operator unfamiliar with the equipment.

Zero Air / Zero Energy Loss Condensate Drains

Zero Air/Zero Energy Loss Condensate Drains are designed for economical removal of unwanted water, oil emulsions, and other liquids.

Higher Flow Rate ASME Code Compressed Air Filters 3IN to 10IN Line Size

Parker Balston higher flow rate ASME code stamped compressed air filters offer high efficiency coalescing filtration at very high flow rates.

The standard carbon steel units have pressure ratings up to 250psig. All LF/FF series housings are ASME code stamped for the rated maximum operating pressure.

Balston Disposable Filter Units

Parker Balston disposable filter units offer all the advantages of microfiber filter cartridges for high efficiency liquid and gas filtration combined with the economics and convenience of complete disposability.

FFC-110 Compressed Air & Gas Filters - Up To 800 PSIG

Finite's inline compressed natural gas FFC-112 filter Series features a light weight robust construction and is is designed to protect critical engine components from contaminants in CNG fuel.

Compressed Air & Gas Filter - Up to 3600 PSIG - FFC-213

Finite's Inline compressed air and gas FFC-213 filter series is used onboard heavy duty truck and bus CNG(Compressed Natural Gas) powered vehicles.

Vacuum Pump Inlet Filters

Vacuum Pump Inlet Filters prevent oil back streaming from the pump to the evacuated chamber and protect the pump from damage by submicron particles

Heatless Desiccant Air Dryer

Parker Airtek TW Series Heatless Twin Tower Desiccant Air Dryers remove contaminants in compressed air systems using Pressure Swing Adsorption (PSA) technology. Pressure dewpoint of -40°F (-40°C) and flowrate of 10 - 6000 scfm depending on model.

Compressed Air & Gas Filters - Up to 800 PSIG - FFC-110

Parker Finite inline compressed air and gas FFC-110 filter series is often used onboard CNG (Compressed Natural Gas) powered vehicles.

Compressed Air Dryers, Membrane for Coordinate Measuring Machines

Balston Air Dryers for Coordinate Measurement Machines (CMM) combine superior coalescing technology with a proven, innovative membrane system to supply clean, dry compressed air with a constant dewpoint to 35°F (2°C).

Compressed Air & Gas - Up to 232 PSIG - Zero Loss Drains

Finite's zero loss condensate drains are desinged for economical removal of unwanted water, oil, emulsions, and other liquids. These drains will only open when liquid is present and will not allow compressed air to escape from the system.

Dual-Stage Compressed Air Filters - BA Series

Parker’s Dual-Stage Compressed Air Filter BA Series are designed to be used as point-of-use breathing air filters. This combination unit contains both a fine grade coialescing filter element and an activated carbon vapor removal element.

Compressed Air and Gas - Up to 800 PSIG - M-Series

Parker’s Finite filters make it possible to improve process efficiency and provide optimal process protection.

Nitrogen Generator For Beverage Dispense

Building on Parker's history of over 45 years of producing Nitrogen Generators, they are now offering a nitrogen gas generator specifically designed to meet the needs of retail coffee establishments. Parker nigtrogen generators eliminate the danger, inconvenience and high costs ofd truck delivered nitrogen.

Contact a Dedicated TFS Representative

TFS has developed an extensive product offering through partnerships with industry leading manufacturers. Count on us to meet your needs while improving your facility’s operation and efficiency.